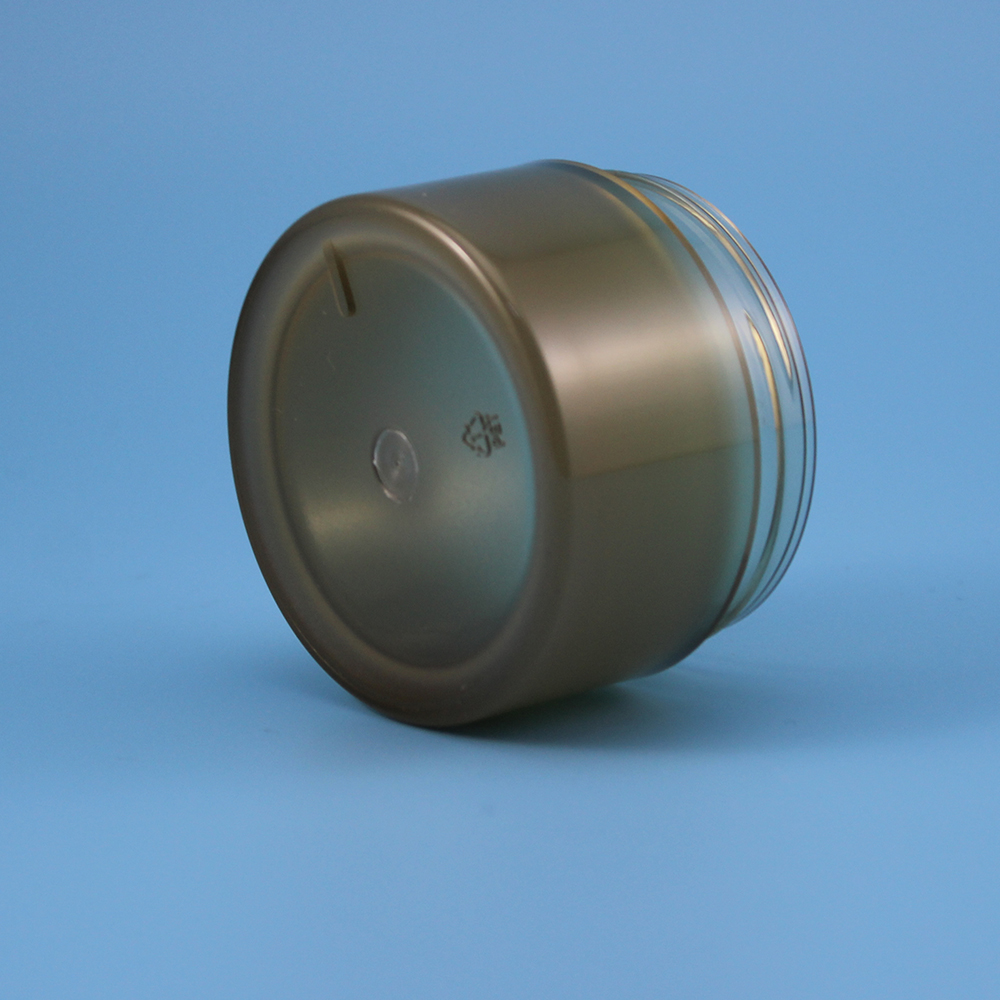

PCR packaging

PCR means Post-Consumer Recycled Plastic, and generally refers to plastics such as PET, PP and HDPE which are widely used in our daily life and relatively easy to recycle. Their second life will be started while they are used in the new packaging.

Why use PCR in the packaging? Principally, because it is friendly to the environment. Virgin plastics are generally come from fossil fuels. Recycling the plastic can reduce the use of fossil fuels and has massive benefits to the environment. Now many countries around the world are making legislation to force the use of PCR. Using PCR can be compliant with regulations. For more, using PCR adds a responsible element to your brand and shows the market what you care. More and more people will pay more attention to the products packaged in PCR packaging, making your product more attractive, charming, and valuable.

What about the drawbacks to using PCR? Firstly, the color is different to the virgin plastic since the PCR material may contain flecks. Then PCR material may not be used in pharmaceutical applications where there is any risk due to contamination. Furthermore, it can be more challenging to mold or production. But once accepted and managed, all these points can be accommodated and PCR can be putted into suitable products. You would not have to use 100% PCR and even 10% is a good start.

PCR bring us the concept of material recycling. During daily processing, we should focus on R&D, design, and production, to better the cycling and the environment.